● Indima yokuqengqeleka kweebheringiiinjini

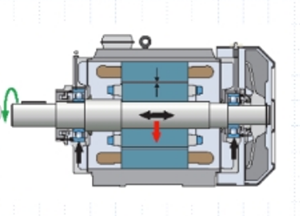

1, Xhasa i-rotor.

2, Ukubekwa kweRotor.

I-3, ukuqinisekisa ukuba ubukhulu be-gap yomoya, iyunifomu ukusuka kwi-shaft ukuya kwisihlalo sokudlulisa umthwalo ukukhusela i-motor ukusuka kwisantya esiphantsi ukuya kwisantya esiphezulu.

4, ukunciphisa ingxabano, ukunciphisa ilahleko.

Yintoni ekufuneka iqondwe ngokucacileyo kukuba iibheringi kwi-motor azithwali umthwalo we-torque ye-motor, ngoko ke into ebizwa ngokuba yimeko yokungabikho komthwalo wemoto inefuthe elincinci kwiibheringi.

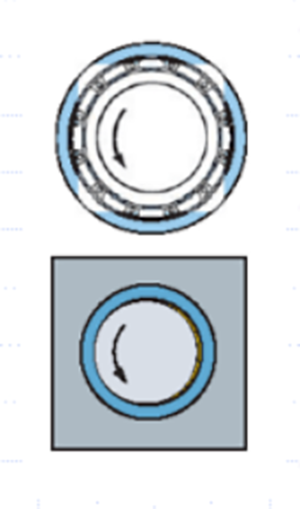

● Ukungqubana

I-1, kunye noburhabaxa bomphezulu woqhagamshelwano, ubunzima, kunye neemeko zokuthambisa - i-coefficient of friction.

2, ukukhuhlana okumileyo > ukukhuhlana okutyibilikayo

3, i-coefficient ye-friction sliding 0.1-0.2.

4, ukuqengqeleka komlinganiso wengxabano 0.001-0.002.

I-5, ukukhuhlana kwe-fluid dynamics - iibheringi ezicacileyo.

Iibheringi zinciphisa ukukhuhlana ngoomatshini kwaye ukuthambisa kunciphisa ukukhuhlana ngokwekhemikhali. Ke ngoko, kuyimfuneko ukuqonda ukungqubana ngaphambi kokuqonda iibheringi.

● Ukuqengqeleka kunye neeBearings eziPlain

Iibheringi eziqengqelekayo

I-1, I-motor inokubekwa ngokuthe tye okanye ngokuthe nkqo.

2. Zinokuqhutywa kuluhlu olubanzi lwezantya.

Isilayidi sokuThweba

I-1, Ukubekwa kwemoto kufuneka kuyilwe kwangaphambili.

I-2, inokuqhutywa kuphela ngaphakathi kwinqanaba lesantya esisebenzayo.

I-3, i-torque enkulu yokuqalisa, ayinakubaleka ngesantya esiphantsi.

Iibhereyidi eziqengqelekayo kunye neebheringi ezicacileyo zeenjini, ukongeza kwimowudi yokhuhlane eyahlukileyo, kukho umahluko kwisicelo.

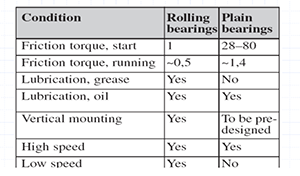

● Ukuthelekiswa kweebheringi eziqengqelekayo kunye neebheringi ezicacileyo

Owona mahluko mkhulu phakathi kweebheringi eziqengqelekayo kunye neebheringi ezicacileyo ngumahluko wokukhuhlana. Umahluko kwingxabano uzisa umahluko kwiimeko zesicelo. Ngoko ke, kuyimfuneko ukukhetha uhlobo lokuthwala ngokwemiqathango yesicelo.

● Iibheringi ezisetyenziswa ngokuqhelekileyo kwiimoto zoshishino

1, Iibheringi zebhola ezinzulu ze-DGBB.

2, Cylindrical Roller Bearing CRB.

3, CARB.

I-4, iibheringi ezigqunyiweyo I-INSOCOAT.

5, iibheringi zeCeramic.

6, Ukuthwala i-Encoder.

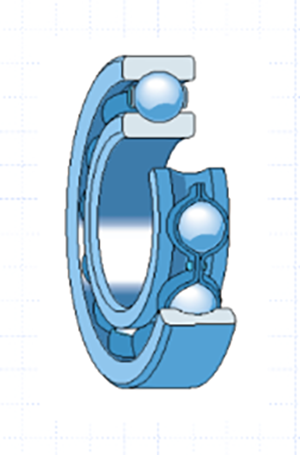

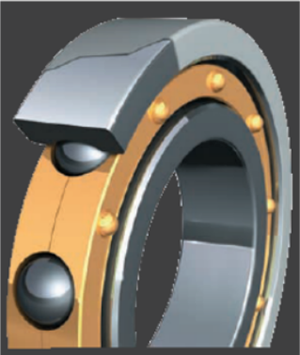

● Iimpawu eziphambili zeebheringi zebhola ze-groove ezinzulu

I-1,Umthamo ogqwesileyo we-axial kunye ne-radial ethwele umthwalo wenza kube lukhetho lokuqala kwiinjini ezincinci kunye neziphakathi.

2, Umthwalo wangaphambili unokusetyenziswa yintlakohlaza yamaza ukwenza imoto ibaleke ngokuzolileyo nangokuthembekileyo.

I-3, iindlela ezahlukeneyo zokutywina ukulungelelanisa iimfuno ezahlukeneyo.

4,Igrisi yobushushu obubanzi ingasetyenziselwa ukubaleka kuluhlu olubanzi lobushushu.

Iibhodi zebhola zegroove ezinzulu lolona hlobo luxhaphakileyo lweebheringi zombane, ezibalelwa ngaphezulu kwe-70% yokusetyenziswa kweemoto zeshishini.

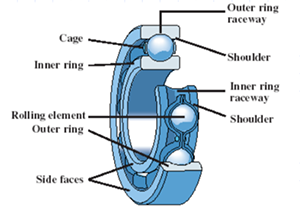

● Ukuqulunqwa kweebheringi zebhola ze-groove ezinzulu

1, umsesane wangaphandle

2, iringi yangaphakathi

3, Ikheji

4. Umzimba ojikelezayo

5. Isigqubuthelo sothuli (isigqubuthelo sokutywina)

Ukuqonda amacandelo eebheringi kunceda ukubonakaliswa kobunjineli kwiinjineli.

● Ukuthwala iCage

Ikheji yentsimbi enesitampu: yomelele, iyamelana nobushushu obuphezulu.

Ikheji yeNyiloni yeB: Isantya esiphezulu sokubaleka, ingxolo ephantsi, ubushushu obusebenzayo ukuya kuthi ga kwi-120 degrees.

iqondo lobushushu ukuya kuthi ga kwi-120 degrees Celsius.

C Ikheji yobhedu eyenziwe ngomatshini: Yomelele, ingasetyenziswa kwindawo yokungcangcazela.

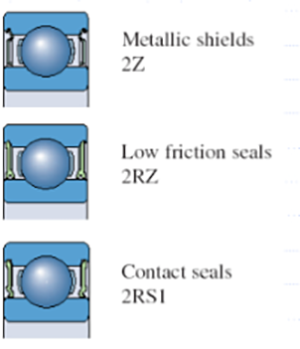

● Ukuthwala amatywina

I-1, i-27 - Ukulinganisa isantya esifanayo njengeebheringi ezivulekileyo, umphumo wokutywina ophakathi.

I-2, i-2RZ -Isiphumo esihle sokutywinwa kunye nesantya esifanayo sokukala njengeebheringi ezivulekileyo.

I-3, i-2RS1 (H) -Isiphumo esihle sokutywinwa, ukulinganiswa kwesantya esisezantsi kunesibini sokuqala.

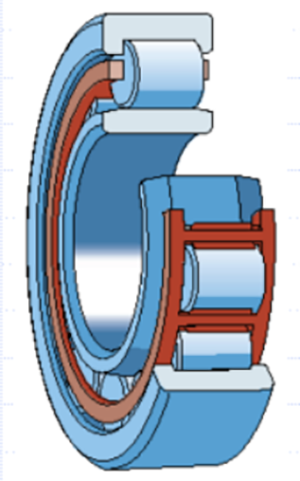

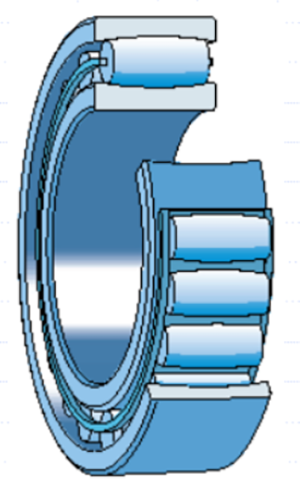

● Iibheringi ze-Cylindrical roller

1, babe nomthamo ongcono wokuthwala umthwalo kuneebheringi zebhola ezinzulu.

I-2, Ngokukodwa ifanelekile kwi-belt drive end of medium and big motors.

3, Uyilo olwahlukeneyo lunokusetyenziswa njengeebheringi ezingezizo indawo okanye iibheringi zokubeka indawo.

4, Iimpazamo ezinkulu zokuxhoma azivumelekanga.

I-Cylindrical rollers inezi mpawu, ezibangela ukukhethwa kohlobo ngokwezi mpawu. Ukhetho oluthile ludinga ukuqwalasela umthamo womthwalo, umthamo wesantya, ukulinganisa ubomi kunye nezinye izinto.

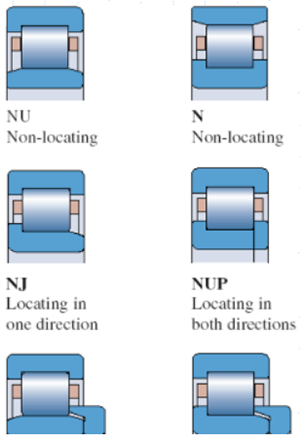

● Iibheringi ze-Cylindrical roller kwiidizayini ezininzi ezahlukeneyo

1, uhlobo lwe-NU - iibheringi ezingabeki ndawo ezineringi yangaphandle enomphetho.

I-2, uhlobo lwe-N - umsesane wangaphakathi unomphetho wegiya, iibheringi ezingekho ndawo.

3, N] uhlobo - umsesane wangaphandle unomphetho wegiya umsesane wangaphakathi unomphetho wegiya kwicala elinye, ukubekwa kwendlela enye.

I-4, i-NUP - kune-N] chwetheza ngaphezu komphetho oshukumayo, ukubekwa kweendlela ezimbini.

Iintlobo ezahlukeneyo zeebheringi ze-cylindrical roller ngokwenene zineempawu ezahlukeneyo. Ke kukho neemeko ezahlukeneyo zosetyenziso. Ngokomzekelo, i-N kunye ne-NU, kwezinye iindlela zokusetyenziswa kwenkqubo, kwezinye zeempawu zokuthambisa i-lubrication, kukho ukungafani.

● iibheringi zeCARB

I-1, ingasetyenziselwa kwimeko apho kukho ukungahambi kakuhle okukhulu phakathi kwe-shaft kunye nomgca ophakathi wokuthwala ((unokuzilungelelanisa).

I-2, Banokuthi bathathe indawo yeebheringi ze-cylindrical roller njengeebheringi ezingenayo indawo kwiimoto zoshishino.

I-3, isangqa esipheleleyo sangaphakathi nangaphandle sinokusetyenziswa kunye nokutshintshwa kwenguqu.

●INSOCOAT

I-1, iphuhliswe kwiibheringi ezingenanto.

I-2, Kukho i-insulating plating layer ye-aluminium oxide kunye ne-resin kwindandatho yangaphakathi okanye yangaphandle ukukhusela i-shaft yangoku ekonakaliseni ukuthwala.

3, Kufuneka ibekwe ekupheleni non-ukuqhuba motor.

I-4, iindlela zokunyuka kunye nokuhla ziyafana nezo zeebheringi eziqhelekileyo.

● Ukuthwala intaka

1, Umzimba oqengqelekayo we-ceramic bearing yi-silicon nitride ceramic material.

I-2, i-rolling body is insulated, isusa i-overcurrent kwi-bearing.

I-3, izinto ze-Ceramic zinobunzima obuphezulu kwaye azikhathaleli ukutshintsha kweqondo lokushisa, ngoko unokuba nexesha elide kwi-lubrication.

I-4, Ukuze kuqinisekiswe umphumo wokugquma, oku kuthwala akuxhotyiswanga ngesigqubuthelo sothuli.

Qaphela: Sithengisa iimotor kuphela, apha nje sazisa ii-motor bearings.

Ixesha lokuposa: Feb-20-2024