Injini ye-Linear stepper, eyaziwa ngokuba yi-imoto ye-stepper ethe tye, yi-magnetic rotor core ngokusebenzisana ne-pulsed electromagnetic field eveliswa yi-stator ukuvelisa ukujikeleza, i-linear stepper motor ngaphakathi kwe-motor ukuguqula i-rotary motion ibe yi-linear motion. Ii-linear stepper motors zingenza i-linear motion okanye i-linear reciprocating motion ngokuthe ngqo. Ukuba i-rotary motor isetyenziswa njengomthombo wamandla ukuguqula ibe yi-linear motion, kufuneka iigiya, izakhiwo ze-cam kunye neendlela ezifana neebhanti okanye iingcingo. Ukwaziswa kokuqala kwee-linear stepper motors kwakungowe-1968, kwaye umfanekiso olandelayo ubonisa ezinye ii-linear stepper motors eziqhelekileyo.

Umgaqo osisiseko weemoto ezijikelezayo eziqhutywa ngaphandle

I-rotor ye-linear stepper motor eqhutywa ngaphandle yimagnethi esisigxina. Xa umbane uhamba nge-stator winding, i-stator winding ivelisa i-vector magnetic field. Le magnetic field iqhuba i-rotor ukuba ijikeleze kwi-engile ethile, ukuze ulwalathiso lwesibini se-magnetic fields ye-rotor luhambelane nolwalathiso lwe-magnetic field ye-stator. Xa i-vector magnetic field ye-stator ijikeleza nge-engile. I-rotor ijikeleza kwi-engile nale magnetic field. Kwi-electrical pulse input nganye, i-electrical rotor ijikeleza nge-engile enye kwaye ihambe inyathelo elinye phambili. Ikhupha i-angular displacement ehambelana nenani le-pulses input kunye nesantya esihambelana ne-pulse frequency. Ukutshintsha i-winding energization kuguqula i-motor. Ngoko ke i-stepper motor rotation ingalawulwa ngokulawula inani le-pulses, i-frequency kunye nomyalelo wokunika amandla i-motor windings yesigaba ngasinye.

Imoto isebenzisa isikrufu njenge-axis ephumayo, kwaye i-drive nut yangaphandle idityaniswe nesikrufu ngaphandle kwemoto, nto leyo ethatha indlela ethile yokuthintela i-screw nut ukuba ingajiki, ngaloo ndlela ifezekisa intshukumo ethe tye. Isiphumo luyilo olulula kakhulu oluvumela ukusetyenziswa kwee-linear stepper motors ngokuthe ngqo kwintshukumo ethe tye yomgca kwiindawo ezininzi ngaphandle kokufakwa kwekhonkco langaphandle loomatshini.

Iingenelo zeemoto eziqhutywa ngaphandle

Iimoto ze-screw stepper ezichanekileyo zingathatha indawo yeesilinda kwiezinye izicelo, ukufezekisa iingenelo ezinje ngokubeka ngokuchanekileyo, isantya esilawulekayo, kunye nokuchaneka okuphezulu. Iimoto ze-linear screw stepper zisetyenziswa kwiintlobo ngeentlobo zezicelo eziquka ukuveliswa, ukulinganiswa ngokuchanekileyo, ukulinganiswa ngokuchanekileyo kolwelo, intshukumo ngokuchanekileyo yendawo, kunye nezinye iindawo ezininzi ezineemfuno ngokuchanekileyo okuphezulu.

▲Ukuchaneka okuphezulu, ukuchaneka kokubeka okuphindaphindwayo ukuya kuthi ga kwi-± 0.01mm

Imoto yokunyathela isikrufu esinemigca inciphisa ingxaki yokulibaziseka kokudityaniswa ngenxa yendlela elula yokudlulisela, ukuchaneka kokubeka, ukuphindaphindwa kunye nokuchaneka okupheleleyo. Kulula ukuyifumana kune "rotary motor + screw". Ukuchaneka kokubeka isikrufu esiqhelekileyo semoto yokunyathela isikrufu esinemigca kunokufikelela kwi-±0.05mm, kwaye ukuchaneka kokubeka isikrufu sebhola kunokufikelela kwi-±0.01mm.

▲ Isantya esiphezulu, ukuya kuthi ga kwi-300m/min

Isantya semoto yokunyathela isikrufu esithe nkqo yi-300m/min kwaye ukukhawulezisa yi-10g, ngelixa isantya se-screw yebhola siyi-120m/min kwaye ukukhawulezisa yi-1.5g. Kwaye isantya semoto yokunyathela isikrufu esithe nkqo siya kuphucuka ngakumbi emva kokusombulula ngempumelelo ingxaki yobushushu, ngelixa isantya "se-rotary" semoto ye-servo kunye ne-ball screw sinqunyelwe kwisantya, kodwa kunzima ukuphucula ngakumbi.

Ubomi obuphezulu kunye nokugcinwa okulula

I-linear screw stepping motor ifanelekile ukuba ilungele ukuchaneka okuphezulu kuba akukho nxibelelwano phakathi kwezinto ezihambayo kunye nezinto ezizinzileyo ngenxa yomsantsa wokufakelwa kwaye akukho kutshabalala ngenxa yesantya esiphezulu sokujikeleza kwee-movers. I-ball screw ayinakuqinisekisa ukuchaneka kwisantya esiphezulu sokujikeleza, kwaye ukungqubana kwesantya esiphezulu kuya kubangela ukutshabalala kwe-screw nut, okuya kuchaphazela ukuchaneka kwentshukumo kwaye akunakuhlangabezana neemfuno zokuchaneka okuphezulu.

Ukukhethwa kwemoto ethe tyaba yedrive yangaphandle

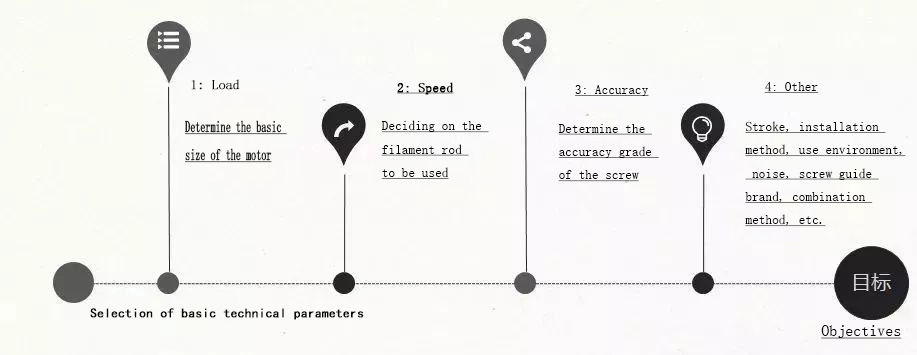

Xa senza iimveliso okanye izisombululo ezinxulumene nokuhamba okuthe tye, sicebisa iinjineli ukuba zigxile kwezi ngongoma zilandelayo.

1. Ingakanani umthwalo wenkqubo?

Umthwalo wenkqubo uquka umthwalo ongashukumiyo kunye nomthwalo oguqukayo, kwaye ubukhulu bomthwalo buhlala bumisela ubungakanani obusisiseko bemoto.

Umthwalo ozinzileyo: ukutyhala okuphezulu okunokumelana nesikrufu xa siphumle.

Umthwalo oguqukayo: ukutyhala okuphezulu okunokumelana nesikrufu xa sishukuma.

2. Ingakanani isantya sokusebenza esithe ngqo semoto?

Isantya sokusebenza kwe-linear motor sinxulumene ngokusondeleyo ne-lead yesikrufu, ukujikeleza okukodwa kwesikrufu kuyilead enye ye-nut. Kwisantya esiphantsi, kuyacetyiswa ukuba ukhethe isikrufu esine-lead encinci, kwaye kwisantya esiphezulu, kuyacetyiswa ukuba ukhethe isikrufu esikhulu.

3. Iyintoni imfuneko yokuchaneka kwenkqubo?

Ukuchaneka kwesikrufu: ukuchaneka kwesikrufu kudla ngokulinganiswa ngokuchaneka okuthe ngqo, oko kukuthi, impazamo phakathi kohambo lokwenyani kunye nokuhamba ngokwethiyori emva kokuba isikrufu sijikeleza ukuze sibe yisangqa esomileyo esikrakra.

Ukuchaneka kokubeka kwakhona: ukuchaneka kokubeka kwakhona kuchazwa njengokuchaneka kwenkqubo ukuze ikwazi ukufikelela kwindawo echaziweyo ngokuphindaphindiweyo, nto leyo eluphawu olubalulekileyo kwinkqubo.

Umqolo ongasemva: umqolo ongasemva wesikrufu kunye nenati xa uphumle xa ubungakanani obuhambelanayo obunokushukunyiswa bungaphezulu. Njengoko ixesha lokusebenza lisanda, umqolo ongasemva uya kwanda ngenxa yokuguguleka. Imbuyekezo okanye ukulungiswa komqolo ongasemva kunokufezekiswa yinati yokususa umqolo ongasemva. Xa kufuneka indawo yokuma kwicala elingaphambili, umqolo ongasemva uya kuba yingxaki.

4. Ezinye izinto onokukhetha kuzo

Le micimbi ilandelayo kufuneka iqwalaselwe kwinkqubo yokukhetha: Ngaba ukufakwa kwe-linear stepper motor kuyahambelana noyilo loomatshini? Uza kuyidibanisa njani into ehambayo ne-nut? Yintoni i-stroke esebenzayo ye-screw rod? Luhlobo luni lwe-drive oluza kuhambelana?

Ixesha lokuthumela: Novemba-16-2022